| Category | Options |

|---|---|

| Material | Zinc Alloy/Low Lead/C46500/CW602n/DZR/Copper/Stainless Steel |

| Imperial Size | 1/2″ – 4″ or as per customer’s request |

| Weight | Customizable according to customer’s requirements |

| Package | Standard export package or Customized |

| Handle Material | Brass/Zinc Alloy/Iron/Cast Iron/Aluminum/Stainless Steel |

| Core Material | Brass/Iron/Cast Iron/Stainless Steel |

| Service | OEM |

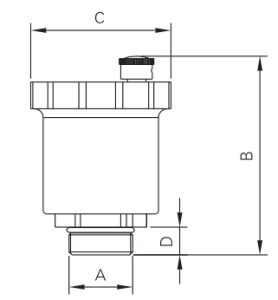

| SIZE | A | B | C | D |

| 3/8 | 3/8” | 67 | 46 | 9.5 |

| 1/2 | 1/2” | 67 | 46 | 9.5 |

| 3/4 | 3/4” | 67 | 46 | 9.5 |

The operational principle of a brass automatic air vent valve involves the automatic detection and expulsion of air from a pipeline system to maintain optimal fluid flow dynamics and pressure equilibrium. Key aspects include:

1. **Air Detection Mechanism:** Equipped with sensors, the valve detects the presence of air within the pipeline, especially at high points where air tends to accumulate.

2. **Automatic Activation:** Upon detecting air, the valve initiates an automatic opening mechanism to release trapped air, preventing air pockets that could impede fluid flow and cause pressure irregularities.

3. **Pressure Regulation:** By expelling air, the valve ensures consistent pressure levels within the pipeline, promoting efficient fluid movement and preventing issues such as cavitation or air locking.

4. **Installation Considerations:** Proper positioning at strategic points within the pipeline system, typically at high elevations, is crucial for effective air elimination and system performance.

5. **Maintenance and Monitoring:** Regular inspection and maintenance are essential to ensure the valve’s continued functionality and to address any potential issues that may arise, safeguarding the overall integrity of the pipeline system.

In essence, the brass automatic air vent valve’s sophisticated operation is designed to optimize fluid flow dynamics, prevent air-related disruptions, and maintain the stability and efficiency of the pipeline system.

| Minimum Order Quantity: | 0 |

| Packaging Details: | Standard Packing |

| Delivery Time: | 40days |

| Payment terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 55000 pcs |

1. WHAT IS YOUR MOQ ?

Usually our MOQ is 3,000pcs. But we accept lower quantity for your tria order. Please feel free to tell us how many pieces you need, we will calculate the cost correspondingly, hoping you can place large orders after checking quality of our products and know our service.

2. HOW LONG IS THE SAMPLE LEAD TIME ?

For existing sample, it takes 2-3 days. They are free. If you want your own designs, it takes 7-10 days, subject to your designs whether they need new MOLD, etc. Anyway, we will response fast to your request.

3. HOW LONG IS THE PRODUCTION LEAD TIME ?

It takes 35 days for MOQ. We have large production capacity, which can ensure fast delivery time even for bulk.

4. WHAT FORMAT OF THE FILE DO YOU NEED IF I WANT MY OWN DESIGN ?

We have our own designer in house. So you can provide JPG, AI, car or PDF, etc. We will make drawing for mold or printing screen for your final confirmation based on technique.

5. WHAT IS YOUR PAYMENT TERM ?

Our payment is TT 30% deposite and 70% against bill of loading copy of TT. PayPal, Western&Union.