| Category | Options |

|---|---|

| Material | Zinc Alloy/Low Lead/C46500/CW602n/DZR/Copper/Stainless Steel |

| Imperial Size | 1/2″ – 4″ or as per customer’s request |

| Weight | Customizable according to customer’s requirements |

| Package | Standard export package or Customized |

| Handle Material | Brass/Zinc Alloy/Iron/Cast Iron/Aluminum/Stainless Steel |

| Core Material | Brass/Iron/Cast Iron/Stainless Steel |

| Service | OEM |

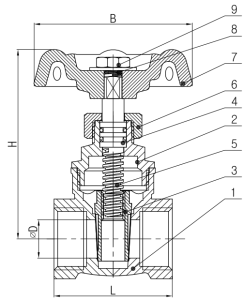

| SIZE | D | H | L | B |

| 1/2” | 12.5 | 64 | 40 | 53 |

| 3/4” | 16 | 66 | 43 | 53 |

| 1” | 24 | 78 | 46 | 59 |

| 1-1/4” | 26 | 95 | 51 | 72 |

| 1-1/2” | 32 | 105 | 55 | 72 |

| 2” | 41 | 125 | 62 | 86 |

detailed description of a Brass Gate Valve:- **Material and Durability**: Brass gate valves are typically made of brass, known for its excellent corrosion resistance and durability, suitable for fluid systems handling non-corrosive media.

– **Working Principle**: A gate valve controls fluid flow by raising or lowering a gate to open or close the passage. When the gate is raised, the passage opens; when it’s lowered, the passage closes. This design allows gate valves to provide good sealing performance.

– **Working Pressure and Temperature**: Brass gate valves are usually designed for specific ranges of working pressure and temperature. The design considers the pressure requirements of the system to ensure the valve’s safety and reliability.

– **Compatible Media**: Suitable for water, air, steam, and other non-corrosive media in fluid systems, commonly used in applications such as building services, HVAC, and water supply systems.

– **Connection Type**: May include threaded connections, flanged connections, or other types to ensure secure installation and sealing.

– **Size Specifications**: Gate valves are sized based on parameters like diameter, length, and weight to suit different pipeline system requirements.

– **Operation**: Gate valves are typically manually operated using a handwheel to control the raising and lowering of the gate. They can also be equipped with electric or pneumatic actuators as needed.

– **Applications**: Commonly used in situations where directional control of fluid flow is required, such as water supply systems, industrial fluid control, enabling quick opening or closing of fluid passages.

– **Maintenance and Care**: Regular checks on the valve’s sealing performance, cleaning of the gate and seat, ensure smooth operation and effective sealing, prolonging the valve’s lifespan.

Brass gate valves are a common and important type of valve known for their good sealing performance and durability, suitable for various fluid control systems handling non-corrosive media. If you need more information or have any other questions, feel free to let me know.

| Minimum Order Quantity: | 0 |

| Packaging Details: | Standard Packing |

| Delivery Time: | 40days |

| Payment terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 55000 pcs |

1. WHAT IS YOUR MOQ ?

Usually our MOQ is 3,000pcs. But we accept lower quantity for your tria order. Please feel free to tell us how many pieces you need, we will calculate the cost correspondingly, hoping you can place large orders after checking quality of our products and know our service.

2. HOW LONG IS THE SAMPLE LEAD TIME ?

For existing sample, it takes 2-3 days. They are free. If you want your own designs, it takes 7-10 days, subject to your designs whether they need new MOLD, etc. Anyway, we will response fast to your request.

3. HOW LONG IS THE PRODUCTION LEAD TIME ?

It takes 35 days for MOQ. We have large production capacity, which can ensure fast delivery time even for bulk.

4. WHAT FORMAT OF THE FILE DO YOU NEED IF I WANT MY OWN DESIGN ?

We have our own designer in house. So you can provide JPG, AI, car or PDF, etc. We will make drawing for mold or printing screen for your final confirmation based on technique.

5. WHAT IS YOUR PAYMENT TERM ?

Our payment is TT 30% deposite and 70% against bill of loading copy of TT. PayPal, Western&Union.