| Category | Options |

|---|---|

| Material | Zinc Alloy/Low Lead/C46500/CW602n/DZR/Copper/Stainless Steel |

| Imperial Size | 15mm ,22mm or as per customer’s request |

| Weight | Customizable according to customer’s requirements |

| Package | Standard export package or Customized |

| Handle Material | Brass/Zinc Alloy/Iron/Cast Iron/Aluminum/Stainless Steel |

| Core Material | Brass/Iron/Cast Iron/Stainless Steel |

| Service | OEM |

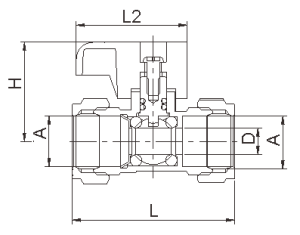

| SIZE | D | A | L | L2 | H |

| 15×15 | 8 | 15.2 | 49 | 33.5 | 31 |

| 22×22 | 12 | 22.2 | 61.8 | 33.5 | 31 |

Isolation valves are essential components within medical gas pipeline systems (MGPS), serving to effectively manage fluids by halting the flow of process fluids for maintenance or safety purposes. These valves also offer the flexibility to automate flow path selection, enabling seamless adjustments in flow paths to meet specific operational requirements.

Available in sizes ranging from sizes 15mm, 12mm, 22mm, 28mm, 35mm, 42mm, 54mm, 67mm, 76mm, 92mm, 108mm., isolation valves are tailored to suit diverse pipeline needs, ensuring compatibility and optimal performance within the system. It’s important to note that the classification of a valve as an isolation valve is based on its intended function within the process piping circuit, emphasizing its pivotal role in fluid control rather than its design specifics.

When engineering and selecting the right isolation valve, critical considerations include pressure and temperature ratings, valve classification and orientation, process conditions, flow rate (Cv), manual or automatic operation, pipe connections, service life requirements, adherence to industry standards, system performance, and total cost of ownership. By meticulously evaluating these factors, engineers can guarantee the efficient and reliable operation of isolation valves within their systems, upholding safety and performance standards in medical gas applications.

| Minimum Order Quantity: | 0 |

| Packaging Details: | Standard Packing |

| Delivery Time: | 40days |

| Payment terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 55000 pcs |

1. WHAT IS YOUR MOQ ?

Usually our MOQ is 3,000pcs. But we accept lower quantity for your tria order. Please feel free to tell us how many pieces you need, we will calculate the cost correspondingly, hoping you can place large orders after checking quality of our products and know our service.

2. HOW LONG IS THE SAMPLE LEAD TIME ?

For existing sample, it takes 2-3 days. They are free. If you want your own designs, it takes 7-10 days, subject to your designs whether they need new MOLD, etc. Anyway, we will response fast to your request.

3. HOW LONG IS THE PRODUCTION LEAD TIME ?

It takes 35 days for MOQ. We have large production capacity, which can ensure fast delivery time even for bulk.

4. WHAT FORMAT OF THE FILE DO YOU NEED IF I WANT MY OWN DESIGN ?

We have our own designer in house. So you can provide JPG, AI, car or PDF, etc. We will make drawing for mold or printing screen for your final confirmation based on technique.

5. WHAT IS YOUR PAYMENT TERM ?

Our payment is TT 30% deposite and 70% against bill of loading copy of TT. PayPal, Western&Union.