| Category | Options |

|---|---|

| Material | Zinc Alloy/Low Lead/C46500/CW602n/DZR/Copper/Stainless Steel |

| Imperial Size | 1/2”-4” or as per customer’s request |

| Weight | Customizable according to customer’s requirements |

| Package | Standard export package or Customized |

| Handle Material | Brass/Zinc Alloy/Iron/Cast Iron/Aluminum/Stainless Steel |

| Core Material | Brass/Iron/Cast Iron/Stainless Steel |

| Service | OEM |

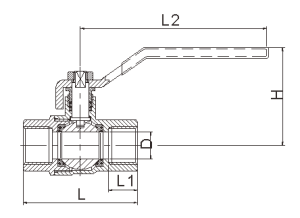

| SIZE | D | L | L1 | H | L2 |

| 3/8″ | 10 | 40.5 | 10 | 40 | 80 |

| 1/2″ | 13.5 | 46.2 | 9.5 | 45 | 80 |

| 3/4″ | 17 | 56.5 | 12 | 47 | 80 |

| 1″ | 21 | 59.8 | 12.5 | 57 | 95 |

| 1 1/4″ | 27 | 72 | 13.5 | 68 | 130 |

| 1 1/2″ | 32 | 88.5 | 16 | 70 | 150 |

| 2″ | 45 | 105 | 18.5 | 77 | 150 |

| 2 1/2″ | 65 | 135 | 30 | 100 | 225 |

| 3″ | 68 | 131 | 22 | 107 | 245 |

| 4″ | 84 | 162 | 25 | 120 | 245 |

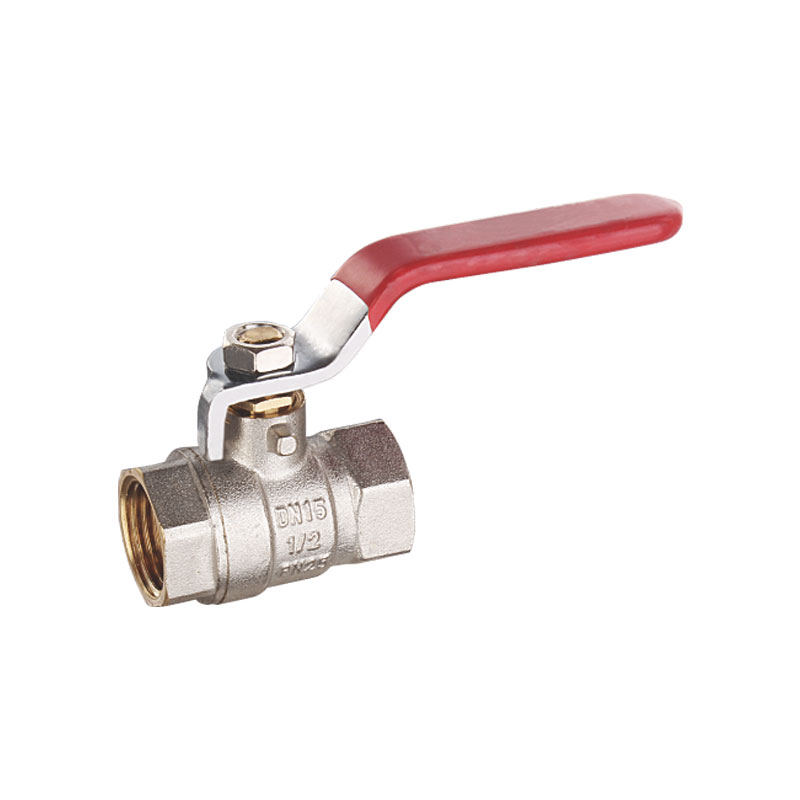

More product information about Long handle PN25 full bore ball valve

The Long handle PN25 full bore ball valve, is a high-performance valve designed to provide efficient flow control in various industrial and commercial applications. This valve offers exceptional durability, ease of operation, and reliable performance, making it an ideal choice for controlling the flow of fluids or gases in demanding environments.

ball valve features a long handle design, allowing for effortless manual operation. The extended handle provides increased leverage, making it easier to turn the valve on or off, even in applications where high pressure or tight seals are involved. The long handle also enables precise control over the flow, allowing for smooth adjustment and positioning of the valve.

Designed for superior functionality, ball valve boasts a full bore design. This means that the internal diameter of the valve is the same as the pipe diameter, ensuring minimal flow restrictions. The full bore configuration provides optimum flow capacity, reducing pressure drop and maximizing efficiency in fluid or gas transportation.

The PN25 rating of ball valve indicates its pressure class. With a PN25 designation, this valve is designed to withstand pressures up to 25 bar, making it suitable for a wide range of applications requiring medium to high pressure handling. The robust construction of the valve, combined with its high-pressure rating, ensures its suitability for use in industrial systems, pipelines, HVAC installations, and more.

Constructed from high-quality materials, such as durable brass or stainless steel, ball valve guarantees exceptional durability and resistance to corrosion. These materials are chosen for their strength and ability to withstand harsh operating conditions, ensuring the valve’s longevity and reliability even in challenging environments.

ball valve is designed for quick and easy installation. It is available in various sizes, ranging from small to large diameters, allowing for compatibility with different pipe dimensions. The valve is typically equipped with threaded or flanged connections, enabling straightforward integration into existing piping systems.

The valve’s ball mechanism is engineered for reliable and efficient performance. It features a precision-machined ball with a bore through its center. When the valve is opened or closed, the ball rotates within the valve body, providing a full flow path or shutting off the flow completely. This design ensures a tight seal and minimizes leakage, enhancing the overall efficiency and effectiveness of the valve.

ball valve also offers versatility in terms of the media it can handle. It is suitable for a wide range of fluids and gases, including water, oil, gas, and more. This versatility makes it a valuable component in various industries, including oil and gas, chemical processing, water treatment, and HVAC systems.

| Minimum Order Quantity: | 0 |

| Packaging Details: | Standard Packing |

| Delivery Time: | 40days |

| Payment terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 55000 pcs |

1. WHAT IS YOUR MOQ ?

Usually our MOQ is 3,000pcs. But we accept lower quantity for your tria order. Please feel free to tell us how many pieces you need, we will calculate the cost correspondingly, hoping you can place large orders after checking quality of our products and know our service.

2. HOW LONG IS THE SAMPLE LEAD TIME ?

For existing sample, it takes 2-3 days. They are free. If you want your own designs, it takes 7-10 days, subject to your designs whether they need new MOLD, etc. Anyway, we will response fast to your request.

3. HOW LONG IS THE PRODUCTION LEAD TIME ?

It takes 35 days for MOQ. We have large production capacity, which can ensure fast delivery time even for bulk.

4. WHAT FORMAT OF THE FILE DO YOU NEED IF I WANT MY OWN DESIGN ?

We have our own designer in house. So you can provide JPG, AI, car or PDF, etc. We will make drawing for mold or printing screen for your final confirmation based on technique.

5. WHAT IS YOUR PAYMENT TERM ?

Our payment is TT 30% deposite and 70% against bill of loading copy of TT. PayPal, Western&Union.