| Category | Options |

|---|---|

| Material | Zinc Alloy/Low Lead/C46500/CW602n/DZR/Copper/Stainless Steel |

| Imperial Size | 1/2″ – 4″ or as per customer’s request |

| Weight | Customizable according to customer’s requirements |

| Package | Standard export package or Customized |

| Handle Material | Brass/Zinc Alloy/Iron/Cast Iron/Aluminum/Stainless Steel |

| Core Material | Brass/Iron/Cast Iron/Stainless Steel |

| Service | OEM |

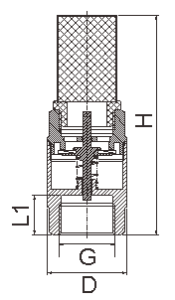

| SIZE | D | L | H |

| 1/2″ | 35 | 15 | 55 |

| 3/4″ | 40 | 16 | 62 |

| 1″ | 47 | 19 | 65 |

| 1 1/4″ | 55 | 20 | 75 |

| 1 1/2″ | 65 | 22 | 80 |

| 2″ | 75 | 24 | 85 |

Premium Material: This spring loaded check valve is made of premium brass and stainless steel material, ensuring durability.

Great Sealing: This spring-loaded check valve comes with a seal, which can prevent liquid from leaking.

Fine Workmanship: This spring loaded check valve comes with fine workmanship, which is quite durable.

COMPACT SIZE: This spring-loaded check valve comes with a compact size, which won’t take up much space.

Tube Supplies: This spring-loaded check valve is a good choice as a tube supply due to its practical function.**Description of Brass Lift Check Valve:**1. **Material**: Brass lift check valves are commonly made of high-quality brass, known for its excellent corrosion resistance and durability, making it suitable for various environmental conditions.

2. **Structure**: The valve consists of essential components such as the valve body, bonnet, valve disc, and spring. The valve disc moves up and down controlled by a spring, allowing for the opening and closing of the valve to regulate the flow direction of the fluid.

3. **Working Principle**: Brass lift check valves control the one-way flow of fluid through the upward and downward movement of the valve disc. When the fluid flow aligns with the valve’s design direction, the valve disc opens to allow fluid passage. Conversely, when the fluid attempts to backflow, the valve disc closes to prevent backflow, ensuring the system operates smoothly.

4. **Applications**: Brass lift check valves find wide applications in water supply systems, HVAC systems, industrial pipelines, and other areas where they prevent backflow of media, safeguarding equipment and system operation.

5. **Advantages**: Brass lift check valves are characterized by their simple and reliable structure, flexible operation, excellent corrosion resistance, and suitability for various fluid control requirements.

In summary, brass lift check valves are a common and reliable type of check valve, playing a crucial role in fluid control and system protection in pipeline systems across diverse industries.

| Minimum Order Quantity: | 0 |

| Packaging Details: | Standard Packing |

| Delivery Time: | 40days |

| Payment terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 55000 pcs |

1. WHAT IS YOUR MOQ ?

Usually our MOQ is 3,000pcs. But we accept lower quantity for your tria order. Please feel free to tell us how many pieces you need, we will calculate the cost correspondingly, hoping you can place large orders after checking quality of our products and know our service.

2. HOW LONG IS THE SAMPLE LEAD TIME ?

For existing sample, it takes 2-3 days. They are free. If you want your own designs, it takes 7-10 days, subject to your designs whether they need new MOLD, etc. Anyway, we will response fast to your request.

3. HOW LONG IS THE PRODUCTION LEAD TIME ?

It takes 35 days for MOQ. We have large production capacity, which can ensure fast delivery time even for bulk.

4. WHAT FORMAT OF THE FILE DO YOU NEED IF I WANT MY OWN DESIGN ?

We have our own designer in house. So you can provide JPG, AI, car or PDF, etc. We will make drawing for mold or printing screen for your final confirmation based on technique.

5. WHAT IS YOUR PAYMENT TERM ?

Our payment is TT 30% deposite and 70% against bill of loading copy of TT. PayPal, Western&Union.